Water treatment describes those industrial-scale processes used to make water more acceptable for a desired end-use. These can include use for drinking water, industry, medical and many other uses. Such processes may be contrasted with small-scale water sterilization practiced by campers and other people in wilderness areas. The goal of all water treatment process is to remove existing contaminants in the water, or reduce the concentration of such contaminants so the water becomes fit for its desired end-use. One such use is returning water that has been used back into the natural environment without adverse ecological impact.

The processes involved in treating water for drinking purpose may be solids separation using physical processes such as settling and filtration, and chemical processes such as disinfection and coagulation.

Biological processes are employed in the treatment of wastewater and these processes may include, for example, aerated lagoons, activated sludge or slow sand filters.

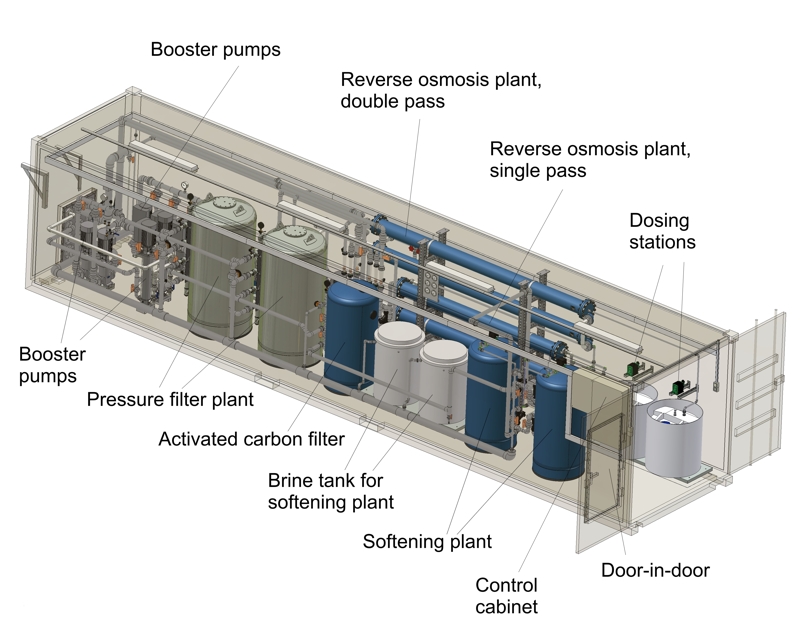

Engineering, Procurement, Construction and Start up of Industrial and Sanitary water treatment units Pretreatment systems such as:

- Clarification (Coagulation, Flocculation and Sedimentation), Design and construction of sand filters and activated carbon filters.

Ion Exchange packages such as Anionic resins, Cationic resins, Mixed bed resins and declassifies.

- Membrane treatment systems (Ultra filtration and Reverse Osmosis).

- Distillation Desalination Systems such as Single Stage Distillation (SSD).

- MED Desalination Units (Multi-Effect Desalination).

- MSF Distillation Units (Multi-Stage Flash Distillation Units).

- VCD Desalination Units (Vapor compression Distillation).